Understanding modern exhaust sensors, accurate diagnostics, and why proper testing saves you money

Oxygen Sensors & Air-Fuel Ratio Sensors: What They Do and Why Proper Diagnosis Matters

Many people hear the term “oxygen sensor” and assume it simply has something to do with oxygen, but don’t really know much beyond that. Let’s break it down and to bring the conversation up to date with today’s vehicle technology.

What an Oxygen Sensor Does

Traditional oxygen sensors are in the exhaust system. The primary (upstream) sensor is usually installed in or near the exhaust manifold. Its job is to measure how much unburned oxygen remains in the exhaust after combustion.

That information is sent to the vehicle engine control unit (ECU). The ECU knows what the oxygen content should be under different driving conditions. Using this information the ECU adjusts the amount of fuel delivered to the engine to maintain the optimal air-to-fuel ratio. This process happens continuously while the engine is running and is critical for:

· Engine performance

· Fuel efficiency

· Reducing harmful emissions

· Monitoring the Catalytic Converter

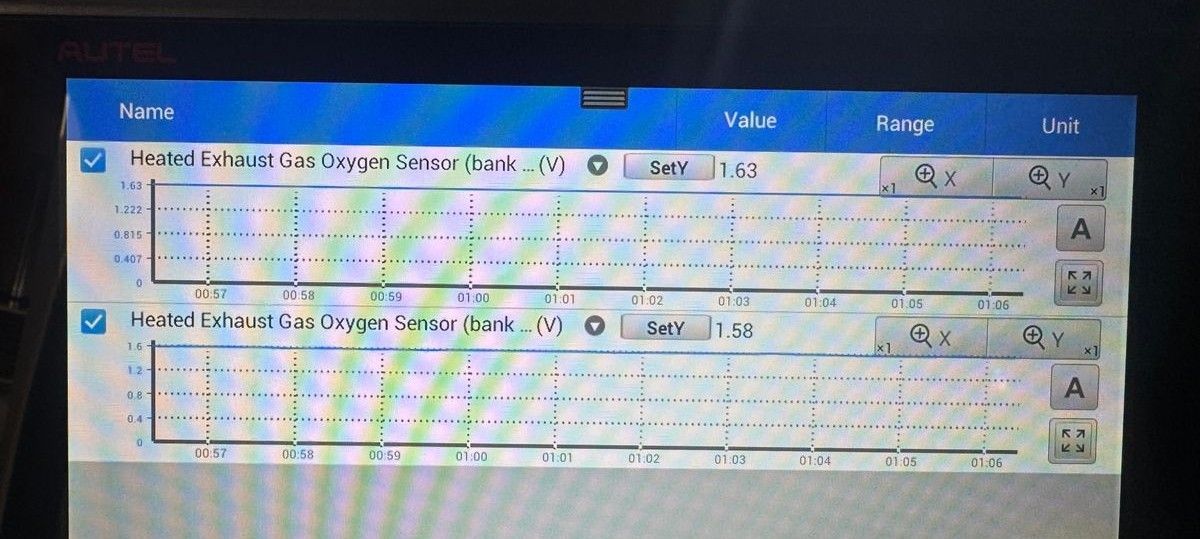

Most vehicles also have a second oxygen sensor located downstream, after the catalytic converter. This sensor measures oxygen levels after exhaust gases have passed through the converter.

The ECU uses this data to determine whether the catalytic converter is doing its job. If the readings are too similar, it may indicate a failing converter.

How Many Sensors Does Your Vehicle Have?

4-cylinder engines typically have two sensors

V6 and V8 engines often have four (one upstream and one downstream for each bank of cylinders)

Some newer vehicles may have even more sensors. Especially if they have multiple catalytic converters that are monitored individually.

Modern Vehicles Use Air-Fuel Ratio Sensors

Here’s where things get more advanced.

Many newer vehicles no longer rely solely on traditional oxygen sensors. Instead, they use air-fuel ratio (AFR) sensors, as well as wideband sensors. These sensors are:

· Much more sensitive

· Far more precise

· Capable of measuring exact air-to-fuel ratios rather than simply “rich” or “lean” conditions

Because of this precision, AFR sensors are also:

· More sensitive to engine fueling problems

· More affected by exhaust leaks, vacuum leaks, and fuel system issues

· They are more difficult to test accurately without professional equipment

As emissions technology continues to evolve, some vehicles now use wideband and other types of AFR sensors. Along with multiple downstream sensors. This allows advanced monitoring strategies to meet stricter emissions standards.

Why Oxygen Sensors Are Often Replaced Needlessly

One common issue we see is unnecessary sensor replacement.

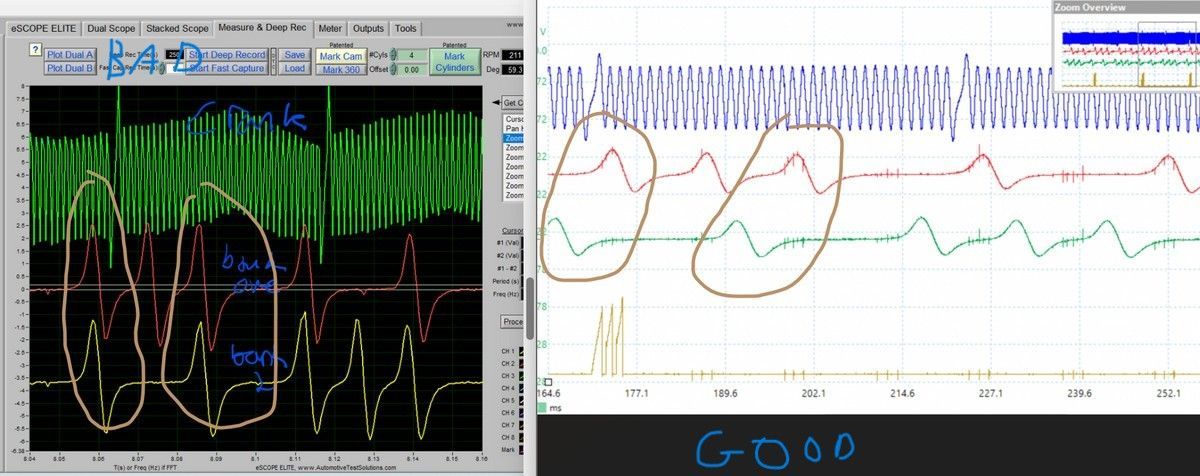

When an oxygen or air-fuel ratio sensor reports readings outside the expected range, it may trigger a Check Engine light and store a trouble code. However, that doesn’t always mean the sensor itself has failed.

The sensor may be:

· Accurately reporting a fueling problem

· Reacting to an exhaust leak

· Responding to a misfire or engine performance issue

· Contaminated by an engine mechanical or other issue (PCV system issue oil or coolant leaks inside cylinders/intake, ETC.)

Replacing the sensor without proper diagnosis often results in:

· The Check Engine light returning

· Wasted money

· The real problem remaining unresolved

A skilled diagnostician understands how these sensors work and tests the entire system before replacing parts.

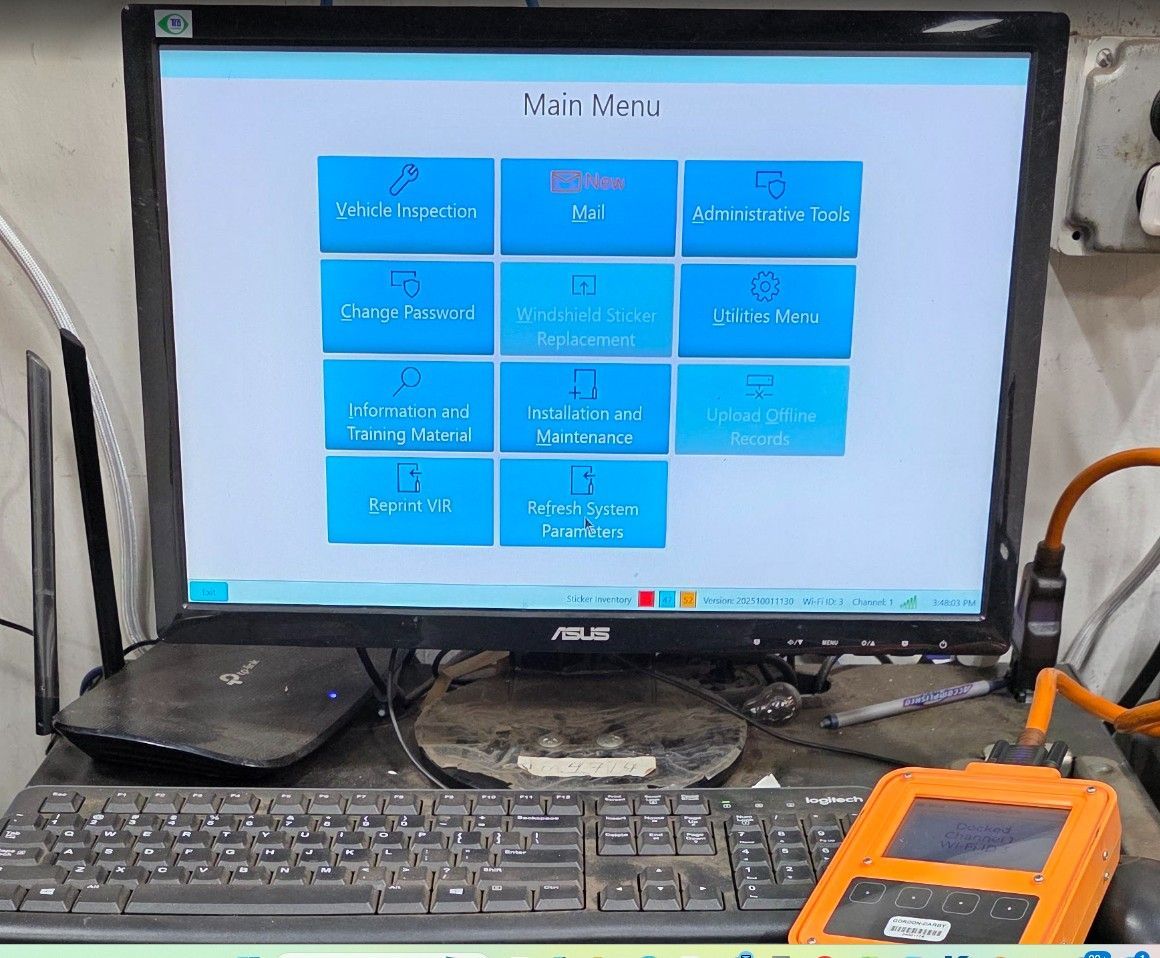

Professional Diagnosis Makes the Difference

Oxygen sensors and air-fuel ratio sensors operate in extremely harsh environments. Between high heat, corrosive exhaust gases, water, and road salt they can wear out or get damaged. When they truly fail, replacement is necessary.

The key is knowing when replacement is needed.

If your Check Engine light comes on and stays on, it’s best to have it inspected by a qualified service technician at Accomplished Auto. The issue may be minor, or it could be something more serious that affects fuel economy, emissions, or engine longevity.

Either way, professional diagnosis ensures the correct repair is made the first time, saving you money and frustration in the long run.